How Do You Fix Low Compression In A Small Engine: A Comprehensive Guide

How To Fix A Lawn Mower With No Compression

Keywords searched by users: How do you fix low compression in a small engine lawn mower low compression symptoms, small engine compression problems, briggs and stratton low compression symptoms, lawn mower compression problem, no compression on pull cord, briggs and stratton lawn mower no compression, small engine compression test, how to fix a lawn mower with no compression

How Do You Increase Compression On A Small Engine?

Increasing engine compression in a small engine is a common goal for many enthusiasts seeking enhanced performance. One effective and budget-friendly approach involves replacing the current head gaskets. By swapping out the traditional composition-style gaskets with steel shim gaskets, you can achieve a noticeable bump in compression ratio. This adjustment not only boosts engine power but also reduces quench clearance, improving overall combustion efficiency. Thus, the process involves a straightforward gasket replacement that can result in significant performance gains for your small engine.

What Are The Three Most Common Causes Of Compression Loss In Small Engines?

Understanding the factors that lead to compression loss in small engines is crucial for maintaining their performance and longevity. Several key issues can contribute to this problem, with the three most common causes being:

-

Holes in the Piston: When there are holes or cracks in the engine’s piston, it can no longer create the necessary compression for proper combustion.

-

Leaking Valves: Valves that do not seal correctly can allow air to escape during the compression stroke, reducing the engine’s overall compression.

-

Blown Head Gaskets: A blown head gasket can result in a breach between the cylinder and the engine’s cooling system, causing compression loss and potential overheating issues.

Other factors such as glazed or splintered cylinder walls, weakened timing belts or cracked chains, worn piston rings, damaged valve springs, seats, and retainers, and a worn-out camshaft can also contribute to compression loss in small engines. Identifying and addressing these issues promptly is essential for maintaining the engine’s performance and preventing costly repairs.

Can You Fix Low Compression In One Cylinder?

Is it possible to address low compression in a single cylinder engine? When dealing with low compression in one cylinder, there’s a troubleshooting technique you can employ. Begin by introducing approximately a teaspoon of oil into the spark-plug hole and then proceed to retest the compression. If you observe an increase in compression levels after this step, it suggests a potential issue with the piston rings. The introduction of oil serves as a temporary seal, aiding in the closure of the gap between the piston rings and the cylinder wall, thereby reducing the pressure loss within the cylinder. This method is valuable for diagnosing cylinder compression problems, as it provides insight into the condition of the rings and their ability to maintain proper compression.

Update 16 How do you fix low compression in a small engine

Categories: Collect 43 How Do You Fix Low Compression In A Small Engine

See more here: ledcbm.com

If you discover you do have low compression, the only solution is to replace the leaking part whether it’s the piston, piston ring, camshaft, head gasket or valves.One of the easiest and most cost-effective methods of increasing engine compression may be done by simply replacing the existing head gaskets. Substituting steel shim gaskets, for example, in place of traditional composition-style units can raise the compression ratio slightly and reduce quench clearance by roughly .If one cylinder has low compression, try pouring about a teaspoon of oil into the spark-plug hole and retesting. If compression increases, it’s likely the rings are stuck or worn. The oil acts as a seal and helps close the gap between the rings and the cylinder wall through which the cylinder is losing pressure.

- Holes in the Piston. …

- Leaking Valves. …

- Blown Head Gaskets. …

- Glazed or Splintered Cylinder Walls. …

- Weakened Timing Belt or Cracked Chain. …

- Worn Piston Rings. …

- Damaged Valve Springs, Seats and Retainers. …

- Worn Out Camshaft.

Learn more about the topic How do you fix low compression in a small engine.

- Top Causes of Low Engine Compression and How to Fix Them

- Increasing Engine Compression – a (Fairly) Easy Path to More …

- Expert Overview: What Causes Engine Compression Loss Anyway?

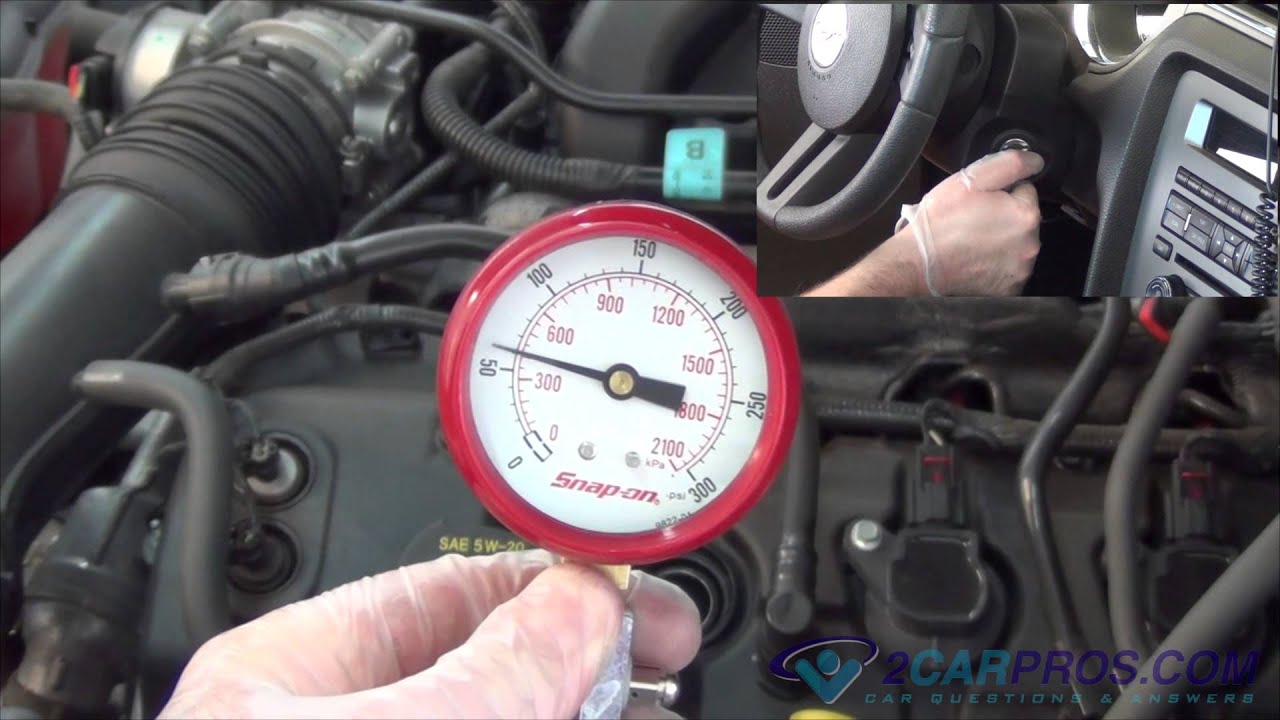

- HOW TO TEST ENGINE COMPRESSION – AMSOIL INC. EU

- How to Test Engine Compression – AMSOIL Blog

- Compression Lessons – MotorTrend

See more: https://ledcbm.com/opinion blog